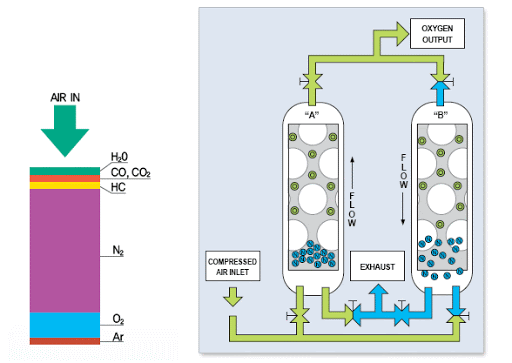

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure. Our gas generators produce Oxygen/Nitrogen gas from atmospheric air based on Pressure Swing Adsorption (PSA) principle by adsorption of oxygen gas using a special grade of imported Zeolite Molecular Sieves (ZMS).

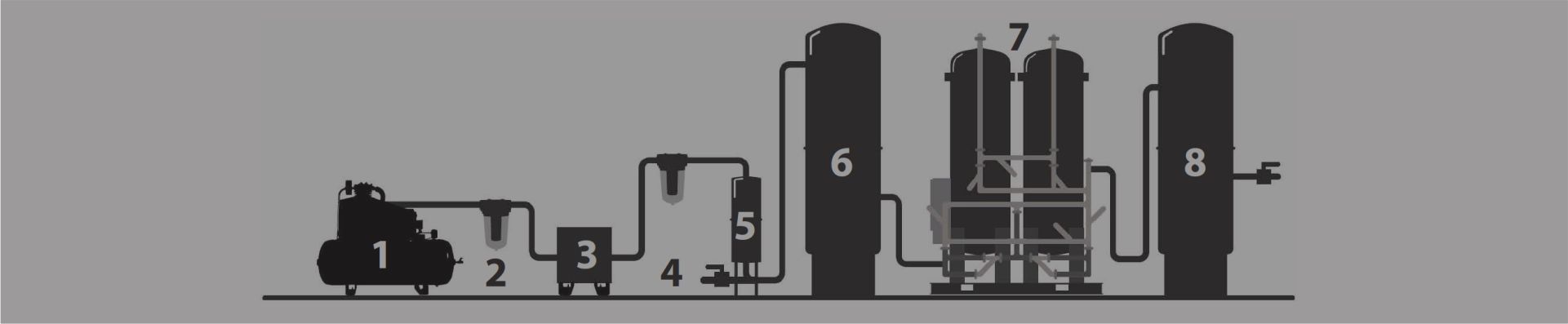

The entire PSA gas generation system can be subdivided into following three parts:

Atmospheric air is compressed by Screw Air Compressor to a required pressure. Moisture and water particles are separated from the compressed air by Air Dryer. Further the dry compressed air passes through a set of Filters and pure compressed air is finally stored in an Air Receiver Tank.

Now the compressed air at a constant pressure is passed through Twin tower PSA module packed with special grade adsorbent i.e. Zeolite molecular sieves (ZMS). The entire operation which is totally automatic controlled by a PLC, quick change over valves. The ZMS separate Oxygen/Nitrogen from air. Like Magnets ZMS strongly attract certain type of molecules of various gases having positive and negative electrical poles. These polar molecules are strongly attracted to Molecular Sieves. For this reason the CO2 & CO in the PSA generated cannot exceed